An interview with In2tec's Emma Armstrong

Could you tell us about In2Tec and its history?

In2tec is an innovative UK company that is at the forefront of changing the way manufacturers produce conventional electronics through state-of-the-art sustainable production techniques that addresses the way electronics are currently recycled.

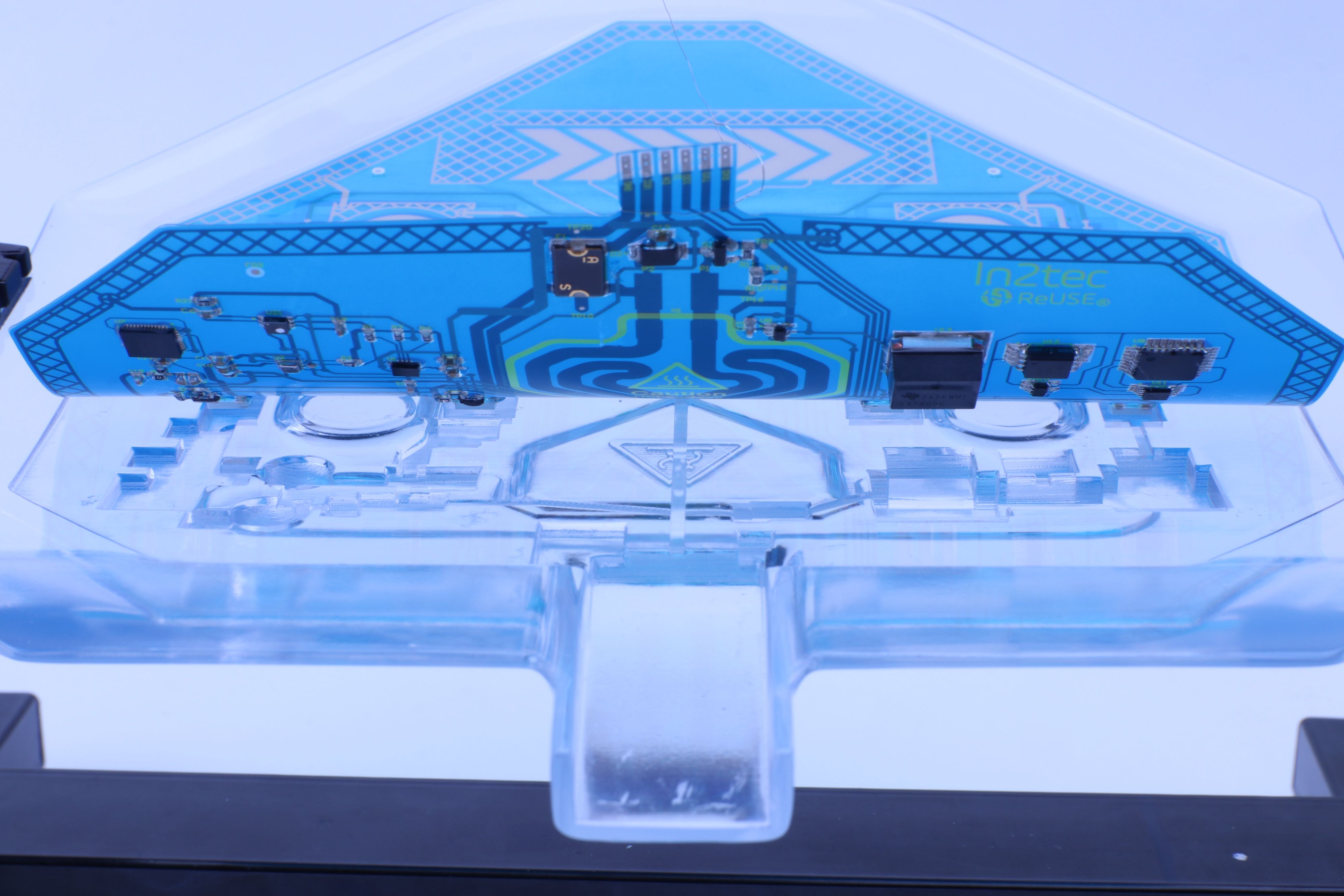

With its roots in providing interface solutions, In2tec has been adding value to its customers around design and integration since it was established in 2001. Building upon this initial success. we have gained expertise in a wide range of innovative interface technologies, and today inspire our customers’ designs that directly benefit from In2tec’s unique capabilities in Flexi-hibrid™ technology and fine-pitch component placement.

However, as the business has evolved, the In2tec team became conscious of the wastefulness within the electronics industry and the destruction caused to the planet.

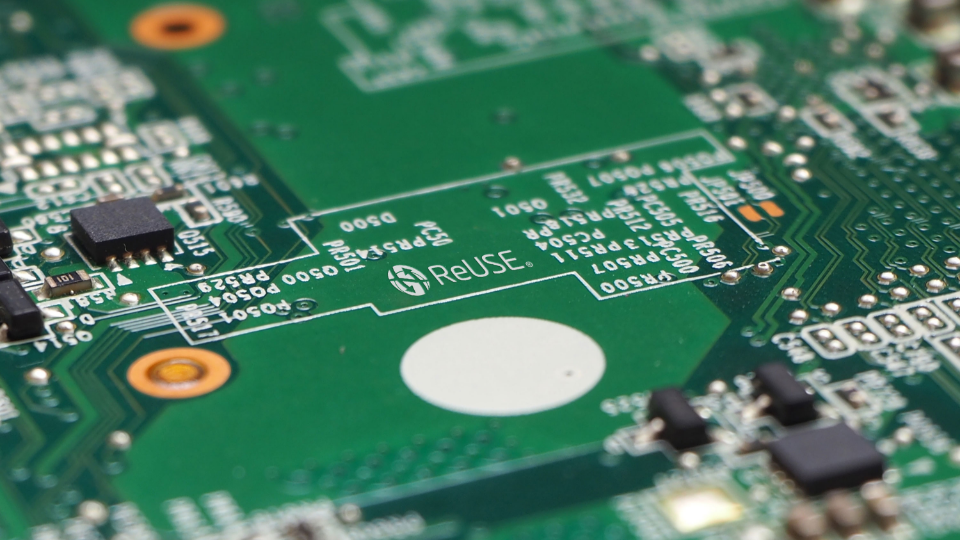

In 2009, In2tec developed a pair of patented technologies – ReUSE®, the manufacturing of unzippable electronics assemblies, and ReCYCLE™ an ultra-low energy disassembly process – that allow full end-of-life disassembly, reuse, and recyclability.

With ReUSE®, not only can the circuit boards be recycled, and the electronic components removed, cleaned, and reused in the manufacturing process, but it makes in-line repair very simple for OEMs when needing to replace a component and extend the useful life of an otherwise wasted printed circuit board assembly (PCBA). Using ReUSE® on 2.5% of the worlds PCBA production per annum would save over 2.4 billion tonnes of C02. It would also save over 25 kilo tonnes of waste electronics going into landfill.

Meanwhile, ReCYCLE™ is an ultra-low energy unzipping process that offers the full supply chain an opportunity to gain value from end-of-life electronics.

What more can industry and government do to advance the circular economy? And Could you tell us about your Sustainability Ethos and why it is core to your business?

According to The Circularity Gap Report, the current global economy is just 7.2% circular (dropping from 9.1% in 2018), meaning that for the most part, materials are mined, created into products, sold, and then disposed of.

This is extremely wasteful and has sadly been the norm for decades. Historically circularity in the electronics industry has been deemed an impossibility due to multiple challenges, including the complexity of the construction of conventional PCBAs and the limited repair, recycling, and reusability options they present.

In 2012, the European Union introduced the Waste Electricals and Electronic Equipment Directive (WEEE) to combat the rising tide of ewaste. The legislation lays down measures to protect the environment and human health by preventing or reducing the adverse impacts of the generation and management of electrical waste. However, it doesn’t go far enough. Many believe that this is the end of the story in the expectation that all their waste electronics have been recycled, but this is not correct. The state of electronics recycling is currently putting future generations in the firing line of a technological and ecological disaster. The waste of precious resources like rare earth metals in electronics has joined the growing list of green issues we read and hear about on a daily basis.

While most materials in consumer electronics can be recycled and reused in new products, such as the non-electronic outer casings and mechanical parts, the electronic components and PCBs cannot.

With PCBs, it is not practical or economical to remove the components meaning these remain and are shredded, burned, or sent to landfill along with the board. Many manufacturers feel that the materials sent to landfill are just an unfortunate by-product of the electronics industry when electronics reach the end of their useful life. But this does not have to be the case. The technology to recycle electronic components has existed for 15 years yet it is only now that sustainability is becoming more of a priority and forming part of the CSR agenda. Up until now the electronics industry has been slow to react and accept its responsibilities to the younger generations who will have to live with the consequences of our actions. At In2tec our mission is to empower manufacturers to collect, refurbish, and recycle technology to conserve rapidly dwindling resources such as gold, silver, and copper. These vital materials are becoming scarce while an estimated £60bn of recoverable materials are wasted every year with some having used less than 20% of their life. It’s an unnecessary waste which can only be eliminated if manufacturers accept that circularity is a must.

In2tec’s unique technology can protect the world for future generations by inspiring sustainable electronics and in our drive to make electronics sustainable we are seeking to achieve a circular vision and remain committed to do whatever is necessary to achieve this goal.

You’ll be speaking in our Industrial Forum at Innovation Zero on 30th April – what are hoping to share with our audiences? Who are you hoping to meet?

I will be providing the audience with in-depth insight into how circularity can be applied to the electronics industry, the inadequacy of current legislation, and inspiring real-world examples of sustainability innovation in action in a variety of sectors. I am hoping to meet like-minded individuals who share our passion and recognise the opportunity in reusing and recycling components. With our technology we can create a groundswell that will not only change the way products are manufactured in the future but encourage reuse of components and materials to bring circularity to the electronics industry and minimise the use of our depleting raw materials and minerals.